Homebrew #26: Sirius Moonlight

¶ by Rob FrieselWith my fermentation chamber proven out, it was time to try my hand at brewing with a lager strain. Granted, looking over my Untappd data, I tend to prefer ales — but I’ve been known to enjoy a Vienna from time to time. And since this is homebrewing and we can do whatever we want… why not throw in a little rye? Or a lot? A Vienna mit Roggen, to coin an auf Deutsch phrase. And so, I present Sirius Moonlight: 1

To be fair, I’d originally started working on this formulation long before the fermentation chamber entered the equation. I’d watched the “Lager Workarounds” episode of Brewing TV and I had some idea from the previous two winters that my basement would be cold enough where 2124 could sit somewhere in the high-50s or low-60s and still turn out some decent flavors. 2 Having zeroed in on Vienna Lager (BJCP 2015 7A.) as the base style, I decided to throw some rye at it because… well, that’s something I would enjoy. Given the choice of yeast and the desire to use approximately 25% rye, I worked out the rest of the grist and the hop schedule by taking notes from a few other representations of the style I’d seen. 3

Granted — this is also about the same time that my dad sent me a copy of Gordon Strong’s Modern Homebrew Recipes, and consequently I’d started to get some… ideas about things like different mash techniques and whether to add certain grains later in the mash process etc. 4

“Don’t get carried away!” (I told myself.) “Keep it simple!”

Fast forward to August. Having discovered that my parents had a totally serviceable but otherwise unplugged chest freezer in their basement, I casually dropped the hint that I could put it to good use; and they were nice enough to hand it over. Combine that with an Inkbird ITC-308S temperature controller 5 and I was ready to do some lagering! And without having to wait until December or January. Come October, given what I had planned, and how far along each formulation was, and how excited I was for any given one of them… my “Vienna mit Roggen” seemed like the way to go.

I went shopping. I was ready to brew.

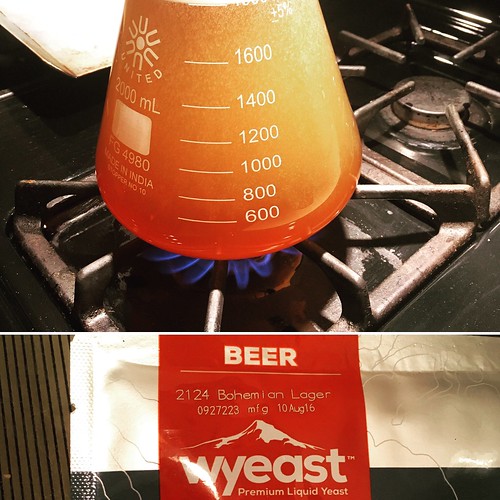

The Starter

First things first, I knew from my reading and research, from forums, from talking with friends, that lager strains need big cell counts. Entering the vital numbers into BeerSmith, it recommended 7 packs of 2124 without the starter. With a starter, I could get away with one (though it recommended two) but I would need a 2.6 liter starter — which is pretty hard to do with a 2 liter flask. And that would only get me to 360 billion of the 395 billion cells that BeerSmith recommended. So I’m maxing out at 2 liters which, let’s be frank, is still pushing the limits of the flask.

Just the same, I cooked up that full 2 liter starter, got it on the stir plate and let it rip for about a day and a half before cold crashing it so I could decant it before pitching. But remember how I just said that I was pushing the limits? Well, sometime in that first 24 hours, the pressure behind the “mini-krausen” of the starter had nudged the flask’s foam stopper loose. It never came totally off, but it was enough for me to raise an eyebrow.

Good sign? Bad sign? Whichever way that went, these were the cells I had to work with.

Brew Day

As long as we’re doing our first lager, may as well do our first home-milled grains, as well!

A few months ago, my uncle had sent me his old grain mill with a nice little note about upping my game. Finally feeling inspired enough, I built my own crude little platform so I could securely balance it on top of a bucket. Come brew day, I decided to finally let rip with that bad boy. After a few minor missteps (i.e., with the roller mill gap) I got it going and was satisfied with the crush.

I mashed in at 148°F, making sure to give it a good stir (and re-take the temperature to be sure) before giving it ye olde towel wrap and walking away for a bit. Despite what I’ve observed in the past, it dropped rather rapidly, and when I checked on the mash a half-hour later, it was down to 144°F. Oh no! I hit it with 4 cups of boiling water to bring it back up to 147°F and walked away again. With 30 minutes remaining we were down to 146°F (OK) and when time came to do the mash-out, I put in the 2½ oz. of chocolate malt that I’d held in reserve. I pseudo-sparged with 1 liter of hot water.

My pre-boil volume was about 3.5 gallons, and approximately ½ gallon more than it should have been. And/but/so that’s what we have to work with so let’s put that burner on! Followed my hop schedule (though I decided mid-boil to omit my originally planned second ounce of Tettnang) and gave it 75 minutes on the flame. Seven minutes to chill to 80°F and that was when things got a little weird.

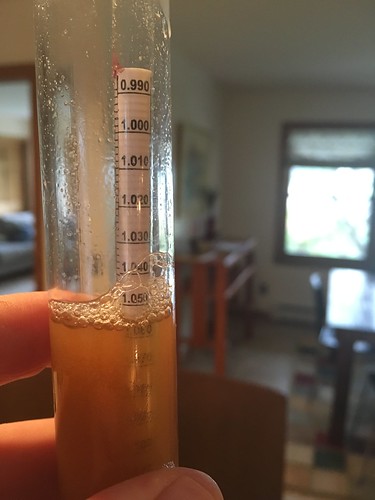

I had almost exactly 3 gallons after the chilling. That seemed about right. So I took a refractometer reading. Looked to be about 27.1%Br — so that should shake out to 1.120 S.G. That seemed high. Diluting with 2 gallons of water should have given me 1.070 — which, you know, is a good 13 points higher than it ought to be. So anyway, 8 liters (i.e., just over 2 gallons) of water went into the fermentor, and I funneled the wort in there. And then I took the hydrometer reading and came up with 1.053. In other words: I would have hit my gravity if it weren’t for the damn +4 offset that I need to deal with.

That seemed… acceptable.

And accepting that, I moved the now full fermentor into the fermentation chamber and checked back on it in a few hours, wherein I discovered it had dropped to pitching temperatures (i.e., 56.1°F). So I decanted and pitched!

Fermentation

With the yeast pitched, the name of the game becomes… waiting. Within a day or so 6 I observed a decent cap of krausen.

I saw some activity in the airlock 7 and nodded with approval. Five days later, as the bubbles slowed down, I added 2½ teaspoons of yeast energizer and gave the carboy some gentle agitation to rouse the yeast. 8

Eight days after pitching, I took my first gravity reading. After accounting for the temperature calibration and the offset, the beer was sitting at 1.012. This seemed almost too good to be true. BeerSmith had estimated a finishing gravity of 1.016 9 and we were already four points below that. If I stopped right there, I’d already have 76.4% apparent attenuation, which is right in the upper end of the range specified by Wyeast. The impatient part of me thought oh hey we could stop right now! but I knew better than that.

First: might the gravity come down any farther? At twelve days it had indeed come down to 1.011. At fifteen days it was sitting tight at that same 1.011.

Second: I remembered my lager science homework and… something about diacetyl rests? Right. I re-set the temperature controller to 62°F and by the next morning it had come up to where it needed to be. Let it rest there for three days.

Third: racked it to a five gallon carboy and put it back into the fermentation chamber to begin the lagering phase. I set the temperature controller to 58°F and dropped it 2°F every 12 hours until it got to 40°F. Once at 40°F, I cleared a space in my beer fridge and moved the carboy into there so I could free up the fermentation chamber for my next brew.

And there it sat for… another 30 days? Give or take?

I’ll admit it, there were several times that I just wanted to keg it and get to pouring. But everything I’d read about lagers and lagering said to be patient. So I waited. And after all that waiting…

Rather uneventfully racked it to a keg. And put it under about 25 PSI for 48 hours; then lowered it to about 12 and sat on it for another four days.

And Sirius Moonlight turned out to be quite a pleasing beer. It’s an at-least-decent (perhaps even good) lager in the Vienna style. Aromas are dominated by a bready malt character with just a hint of spicy notes that are a suggestive blend of the hops and the rye. In the glass, it’s a lovely amber with brilliant clarity 10 and a serviceably persistent off-white crown. There’s rye spice on the tip of the tongue; otherwise flavors lean malty (slightly bready 11 and slightly sweet) and get more bitter as it passes over the tongue and finishes with an earthy and herbal noble hop character. Mouthfeel is smooth and on the light side of medium, with just enough carbonation to make it feel “bright” on the tongue.

I don’t know that it’s exactly a Vienna, 12 but I like it and would make it again. That being said, a second pass at this would lose the chocolate malt (I can hardly detect it anyway 13) and bump the rye up to 30% to make that more assertive. I’d also look at my mash and boiling techniques here to see if there are ways that I could better develop the malt character and color that way. I would also kick the hops up just a little bit, possibly trying some first wort hopping with an ounce or so of Tettnang.

Recipe

The partial mash recipe for Sirius Moonlight is as follows.

Mash Grains

- 3 lb. 14 oz. Briess Goldpils Vienna

- 2 lb. 4 oz. Briess rye malt

- 2½ oz. Briess chocolate malt

Fermentables

3.3 lb. (1 can) Briess Pilsen Light LME (15 min. late addition)

Hop Schedule

- 1 oz. Tettnang (75 min.)

- 1 oz. Perle (10 min.)

Yeast

Wyeast 2124 Bohemian Lager

Prepare a 2000 milliliter starter 2-3 days before brew day.

Brew Day

- Collect 13.51 qt. water and heat to 154.4°F. Mash in; hold at 147.9°F for 90 minutes.

- Mash out. Heat to 168° over 7 minutes; hold for 10 minutes.

- Remove filter bag from water. Squeeze filter bag to extract as much liquid as possible for wort. Sparge with 1 L. water.

- Top off as necessary to approx. 3 gal.

- Bring to a boil. Boil for 75 minutes, following hop schedule described above. Add 3.3 lb. Pilsen Light LME with 15 minutes remaining.

- Cool to 70°F as rapidly as possible and top off the fermentor to reach 5 gal.

- Aerate wort; place in fermentation chamber to cool to pitching temperatures (approx. 56°F).

- Pitch Wyeast 2124 yeast from starter.

Beyond Brew Day

- Allow fermentation to complete (approx. 2 weeks) at approx. 56°F.

- Raise temperature to 62°F for a diacetyl rest; hold for at least 3 days.

- Lager at 40°F for 30 days; if possible, lower temperature gradually.

- Rack to keg. Drop temperature to 38-40°F and connect to CO₂ at 25 PSI.

- After 36-48 hours, turn off gas and purge CO₂ from the headspace.

- Turn gas back on at 12 PSI and wait approx. 4 days.

- Pour and enjoy.

Details

Sirius Moonlight, a Vienna mit Roggen lager by Tilde Gravitywerks

| Original Gravity | 1.053 |

| Final Gravity | 1.009 |

| ABV | 5.8% |

| Attenuation | 82.3% |

| IBU | 25 |

| SRM | 10 |

| Links | Untappd Flickr |

- About that name… My family has been really… “forgiving” — even Stockholm syndrome-esque supportive of — my brewing hobby. And while my wife remains interested only in the consumption side, my kids have gotten interested in (and engaged in) the production side. My boys (appear to) love learning about the science behind it all, and what kind of thought process goes into deciding on styles and ingredients etc. And they keep suggesting different styles (as they flip through my books) and/or ingredients to try and/or (in this case) names to fasten onto a particular beer. And it was with this beer that my youngest asked if we could name this beer after David Bowie. “Sure,” I told him; “did you have a specific reference in mind?” He told me “Let’s Dance” — and while I didn’t personally grasp onto that, we did agree on borrowing the line about “Serious Moonlight”. My older boy (Harry Potter fan that he is) and my wife suggested making the slight play on words. And that stuck.[↩]

- If I’m to believe their research…[↩]

- In particular: the Vienna Lager recipe from Home Brew Beer (Hughes, 2013), as well as “Nothing but Vienna” and “Mexican Vienna”, both from Modern Homebrew Recipes (Strong, 2015).[↩]

- In particular, I got worried that I’d need to do a decoction mash (I didn’t) and that I could avoid some astringency by adding the darkest grains during vorlauf (I did) — or whatever passes for vorlauf with BIAB.[↩]

- With the 12-inch temperature probe, obviously.[↩]

- Not too much waiting, actually.[↩]

- This raised a new question for me. This being the second time that I’d used a carboy cap instead of a drilled stopper (i.e., to accommodate the temperature probe), I wondered if the seemingly low-level of airlock activity was due to a looser seal (i.e., from the carboy cap) or the lower temperatures (i.e., from the fermentation chamber)?[↩]

- As an aside on the agitation: I feel like the jury is out on this… “technique”? I’ve read in a number of articles that this is something that you can do to put the yeast back in suspension in the hopes that they will “clean things up” some more. That being said, agitating is always couched in terms of “gently” so as to avoid splashing and oxidation. I wonder about the oxidation because if you had a vigorous fermentation and you haven’t breached the airlock then it should be covered in a CO₂ blanket. At the same time, if you have breached the airlock (i.e., to add the yeast nutrient) then how much oxygen have you (realistically) introduced? I wonder about this because I’ve used this “agitate to rouse” technique on a few beers and sometimes it seems to be fine and others it seems to have promoted some slight oxidation.[↩]

- Granted, that F.G. was estimated based on a 1.057 O.G.[↩]

- One of my clearest beers yet![↩]

- But not yeasty![↩]

- As-is, I probably would not enter it into a competition; at least not as 7A. I don’t detect any flaws per se, but I believe there’s just enough rye to make it tilt out-of-style. It might work under 31A. (Alternative Grain Beer) or 34B. (Mixed-Style Beer).[↩]

- It was, after all, just there for color.[↩]

About Rob Friesel

Software engineer by day. Science fiction writer by night. Weekend homebrewer, beer educator at Black Flannel, and Certified Cicerone. Author of The PhantomJS Cookbook and a short story in Please Do Not Remove. View all posts by Rob Friesel →4 Responses to Homebrew #26: Sirius Moonlight

Pingback: Homebrew #71: Sirius Moonlight (Mk. II) | found drama

Pingback: Homebrew #81: Half Dark | found drama

Leave a Reply