Homebrew #76: Lupulin-Industrial Complex

¶ by Rob FrieselPerhaps because I live in such a wonderland of New England IPAs, I’d never felt a burning desire to make one. Don’t get me wrong, the challenge itself is tempting — but only 4-ish years and 75 brews into the hobby, there are still so many challenges to choose from! However, when the opportunity to get a little hop hash came around, it seemed like the perfect excuse to take a stab at this. And this brings us to Lupulin-Industrial Complex:

First things first: hop hash?

I’d heard of this stuff before — that hop pellet production actually “leaks” (for lack of a better term) a not insignificant quantity of resins and lupulin powder. 1 It’s this “leakage” which is collected — purportedly off of the pellet-making machinery — and compressed and sold as hop hash. Much like fresh whole cones, they have volatile (i.e., seasonal) availability so it’s not an ingredient you can normally get.

So, when I did my buy for Extinction Event’s hops, I couldn’t help but notice that Yakima Valley Hops had some Comet hop hash in stock. And when I say “couldn’t help but notice” I also mean “couldn’t help but add some to my order”.

But what to make with it? Then I grit my teeth and admitted to myself that there was really only one answer to that.

Brew Day

The night before, I staged my gear and prepped my water. I ran my municipal water through a carbon filter, added the minerals and then (just to be extra safe?) dosed each of the collected volumes with a quarter Campden tablet to drive off any chlorine the carbon filter didn’t otherwise remove.

As winter settled back upon the Vermont landscape, my garage-brewing season was ending. Reluctantly, I moved the brewing operation back into the kitchen and, that morning, got going with the milling and the flame for the strike water and all of that.

Transitioning back into the kitchen didn’t present any real problems 2 and the rest of the morning proceeded pretty much without incident. (Certain heating steps just took a little longer?)

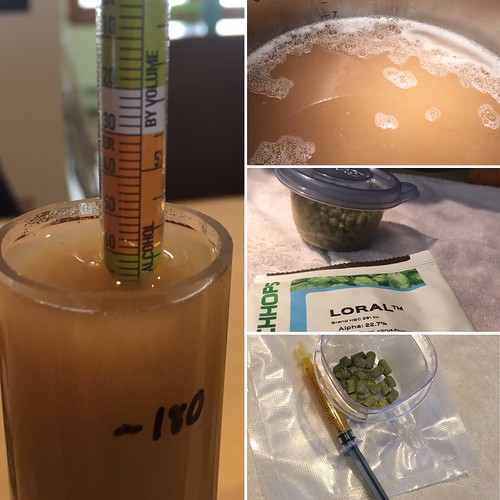

More or less hit all my numbers (1.069 O.G. and just barely shy of the target 5.5 gal. into the fermentor) and pitched my yeast that afternoon.

(A fun aside: this would also be my first time using a “HopShot” as part of the bittering addition. 3)

Fermentation

After the wort had chilled to 65°F, I decanted off most of the supernatant from the yeast starter and pitched a slurry of Omega OYL-052 DIPA Ale. 4 Then I set the ceiling on my controller to 68°F and walked away — letting it free-rise from there.

Twenty-four hours after pitching, I added the first (biotransformation) dry hop charge — 2 oz. of Centennial.

After a couple of days, activity in the blow-off bucket was slowing down, so I bumped up the controller to 70±1°F to encourage complete attenuation and re-metabolizing of any diacetyl.

I pulled a sample for gravity a few days later and saw that it had come down to 1.012 — I expected that this was likely where it would finish. Another gravity reading three days later confirmed this. I added the 4 oz. of Comet hop hash to dry hop at this point.

A Brief Aside About Hop Hash

As I mentioned earlier, I didn’t really know what to expect with the hop hash. I had read a little bit about how it was made, and that it was concentrated and therefore intense. But even with that knowledge, I wasn’t fully prepared for what I would see (and smell) when I finally opened the vacuum-sealed bag.

First of all, before I even saw the green clumps inside, I could smell them. The aromas were intense. Resinous dank weed intense. Granted I realize it’s popular to the point of cliche for brewers to make that comparison — but I can confidently assert that I’ve never made the association more strongly than when opening this bag. And again, because this is such a popular comparison to make, it’s really hard for me to stress just how apt the comparison is here.

Second, the format of the hop hash was… strange? I was expecting something more like a powder. (No clue where I got this idea.) Maybe a compressed powder — but something that would easily break up. Instead, these chunks were sticky and hard. They wanted to stay together. I did eventually work them apart into bean-sized bits, but it took some work.

End of Aside, and Onward to Packaging

After three days on the hop hash, I took one last gravity reading (still 1.012) and transferred the beer to a keg. Sensitive to the “drink fresh” nature of such a hop-forward style, I decided to try out one of those fancy keg lids with a carbonation stone. After chilling the beer to 40°F overnight, I applied about 28 PSI through the carbonation stone 5 for six hours. After that, I transferred the beer to a kegerator and did my first pour later that afternoon.

Overall Impressions

It’s recognizably a New England IPA — and not too shabby for my first attempt.

AROMA. Hop-forward. Medium-high pineapple. Medium mango. Medium tangerine. Moderate grapefruit. Low-moderate pine. Maybe a little lime zest? Low malt impression; a little white bread, but mostly neutral. Low-moderate fruity esters; subtle berry impression. No detectable DMS or diacetyl.

APPEARANCE. Pale gold color. Hazy to the point of opaque, but not turbid — uniform color. Roughtly 2cm white head with loose foam on initial pour. Retention average, but persistent ring of foam. Eventually collapsed completely, though swirling the glass could re-rouse it briefly.

FLAVOR. Follows aroma. Leads with hop impressions. Medium intensity pineapple and grapefruit and tangerine. Moderate mango. Hints of pine resin impression toward the finish, mostly retronasally. Supportive malt character, mostly neutral; moderate white bread notes mid-palate. Soft, moderate bitterness. Suggestion of fruity ester impression throughout; mostly tropical notes. A little “hop burn” through the finish, otherwise smooth. Dry finish though elements of the mouthfeel also mean this isn’t “crisp”. Fruity-sweet impressions linger into the aftertaste. Some sips (not all) have an almost chalky impression retronasally, but that comes and goes and I’m having a hard time placing it.

MOUTHFEEL. Medium body. Medium carbonation. Soft impression overall, with some “hop burn” in the finish. No significant astringency, though that “hop burn” could be read that way. Moderate alcohol warming. Despite body and overall “softness”, those elements do not translate into any significant creamy character.

OVERALL IMPRESSION. Recognizably a New England IPA, and not bad for a first attempt. While not a subdued aromatic intensity, seems to lack some of the “punch” of the style. 6 That said, the first thing that comes to mind is to dry hop at an even higher rate — but that might intensify the “hop burn” which, while common in the style, isn’t exactly desirable. I also suspect that the head retention may have been negatively impacted by the dry hop rate as-is. The pine elements don’t exactly clash, but they seem to throw the other hop elements slightly out of balance. Malt character seems appropriately supportive. No obvious fermentation faults. Reminds me a little bit of Uncanny Valley. 7

And having said all that, it occurs to me that although I drink plenty of NEIPAs, I hadn’t made a study of the style’s production. I’d read a few articles and blog posts, listened to a couple of podcasts… but I hadn’t taken notes. I went into it with a mental checklist like:

- Mostly pils base malt, plus some flaked wheat and/or oats

- Moderate bittering hops, then big on whirlpool, and bigger in the dry hop

- Speaking of dry hopping: biotransformation?

- Speaking of biotransformation: get a strain that’s said to do this

- Oh and don’t forget an chloride-to-sulfate ratio somewhere in the 1.5:1 to 2:1 range

- Also minimize O₂ pick-up

And I mostly checked those boxes as I got this together. So what would I do to improve it?

First, I’d make a better study of the style’s characteristic ingredients and production. Perhaps there are some subtle process tweaks that will make a big difference here. (There’s always room for improvement in the O₂ minimization department.)

Second would be to look at how I might boost the hop intensity, especially in the aroma. I hear these stories about people dry hopping with a pound or more of hops and while I think that’s ridiculous (i.e., diminishing returns) — perhaps adding a third dry hop would do the trick? (Jam it in there perpendicular to the other two?)

Third, I might play with the proportions of the adjuncts a bit. I used equal amounts of flaked oats and flaked wheat, to 20% of the grist. I’m not dissatisfied with the mouthfeel, nor the flavor, so I can’t point to those elements and say with certainty that they need to change. But I also can’t point to the flaked wheat and tell you what it’s contributed; and I do love some Orbital Elevator, so maybe going 3:1 flaked oats to flaked wheat to 20%…? (I’m sure a closer study of the style will have opinions galore on which adjuncts in which proportions.)

Again, I’m satisfied overall with how the beer turned out. The main thing that this beer needed to do was give me a chance to play with the hop hash. And it definitely delivered there.

(P.S. — I would totally brew with hop hash again.)

Recipe

The all-grain (BIAB) recipe for Lupulin-Industrial Complex is as follows:

Water Chemistry

Starting with the Champlain Water District profile as a base:

- 0.59 g/gal. calcium chloride

- 0.58 g/gal. Epsom Salt

- 0.09 g/gal. sodium chloride (salt)

- 1.16 ml/gal. 88% lactic acid

| Ca | Mg | Na | SO₄ | Cl⁻ | HCO₃⁻ |

|---|---|---|---|---|---|

| 69 | 21 | 19 | 81 | 119 | 67 |

Mash Grains

- 5 lb. BEST Pilsen malt

- 5 lb. Briess Pale Ale malt

- 1 lb. 8 oz. BEST Vienna malt

- 1 lb. 8 oz. flaked oats

- 1 lb. 8 oz. flaked wheat

Hop Schedule

- ¼ oz. Galena (60 min.)

- 3 ml HopShot (60 min.)

- 2 oz. Amarillo (10 min. steep/whirlpool at 180°F)

- 1 oz. Cryo Loral (10 min. steep/whirlpool at 180°F)

- 2 oz. Centennial (dry hop; add after 24 hours)

- 4 oz. Comet hop hash (dry hop 3 days)

Yeast

Omega OYL-052 DIPA Ale (1200 ml starter)

Brew Day

- Collect 18.41 qt. water and heat to 166.7°F. Mash in; hold at 152.1°F for 75 minutes. Meanwhile, collect 12.00 qt. water and heat to 197.3°F; add this water to the main mash and hold for 10 min. to mash-out.

- Remove filter bag from water. Squeeze filter bag to extract as much liquid as possible for wort. No sparge. Pre-boil volume should be 6.54 gallons.

- Bring to a boil. Boil for 60 minutes; follow hop schedule as described above.

- Cool to 65°F as rapidly as possible. Post-boil volume should be approx. 5.5 gallons.

- Aerate wort; pitch OYL-052 yeast from starter.

- Start fermentation at 65°F.

Beyond Brew Day

- Allow fermentation to complete (approx. 2 weeks); start at 65°F but allow it to free-rise up to 68°F.

- Add 2 oz. Centennial 24 hours after pitching for biotransformation dry hop.

- When fermentation slows, raise temperature to 70°F to encourage complete attenuation and clean-up of diacetyl.

- Add 4 oz. Comet hop hash to dry hop 3 days.

- Transfer to keg.

- Chill to 40°F and force carbonate to 2.6 volumes. (With a carbonation stone, apply 28 PSI for 6 hours; otherwise apply 13 PSI for a couple of days.)

- Enjoy!

Details

Lupulin-Industrial Complex, a New England IPA by Tilde Gravitywerks

| Original Gravity | 1.069 |

| Final Gravity | 1.012 |

| ABV | 7.6% |

| Attenuation | 81.8% |

| IBU | 37 |

| SRM | 5 |

| Links | Flickr |

- It’s still not 100% clear to me what separates hop hash from lupulin powder from cryo hops. Maybe I should just ask someone knowledgeable.[↩]

- Though I’ll admit that (1) I definitely missed the added power of my propane burner and (2) I missed the pulley for lifting the grain bag.[↩]

- Almost as if I were trying to use every format of hops that I could get my hands on? Any maybe that’s a clue about where the beer name came from?[↩]

- Speaking of firsts, this was my first time working with Omega’s yeast.[↩]

- Which, if you haven’t used one, it sure does make a different sound as the internal pressure tries to equalize.[↩]

- That being said, the day after my first pour, I had a Hill Farmstead Legitimacy with lunch, and the intensity of its hop aromatics were on par with my experience of this batch. Not that I’m comparing my own beer to HFS — more like (as I told my lunch companion): “Imagine two CDs played at the same volume, and one of them is just OK but the other one is really good. I’m comparing the volume.”[↩]

- Though looking over available information on that beer… pretty different hop selection. Not that I was making a direct comparison.[↩]

Leave a Reply