Homebrew #97: Murphy the Lucky Dog

¶ by Rob FrieselTwo motivations at work here. The first, and probably more predictable of them: St. Patrick’s Day was imminent, and I wanted an Irish Stout on draft for the occasion. And the second? I wanted to round out the BJCP’s Category 15 beers. 1 Thus was Murphy the Lucky Dog 2 devised:

Come to think of it, there was a third motivation happening: I wanted to get a feel for how I might pull off some stovetop small batches in our still-new-to-us Seattle home. What better beer to try that out on?

Brew Day

Given the small batch size, I decided to forego a starter and just do a straight pitch from the smack pack. So on brew day, I did just that: smacked the pack of Wyeast 1084 and placed it on top of the refrigerator to puff up while I did everything else.

Milling went quick with roughly half as much grain as I’m accustomed to.

All the filtered water and salts were mixed together in my usual 10 gallon Spike kettle. I’d hoped that maybe ye olde starter kettle would give me enough volume but… alas! even for a “small” beer like this, it was just too small.

Got the flame going and mashed in… just a bit too high. Formulation called for 152.1ºF but there I was at 154.9ºF. Well, OK — I haven’t worried about such a small difference in mash temperature for a long time, so I decided not to worry about that now either. The mash pH read as 5.16 as of 15 minutes into the mash — maybe a little low? but unlikely a major concern. Let the rest of the mash run its course, finishing at 150.1ºF.

After the bag hoist and squeeze, kettle volume was reading 3.75 gal. with a specific gravity of 1.037 according to that (mischievous) refractometer.

The rest is basically a chase scene: boil and add hops and flame out and chill 3 and do some science:

- 2.5 gal. into the fermentor

- 1.050 original gravity

- 64.3% brewhouse efficiency

So… higher-than-planned gravity but lower-than-planned volume translates to a brewhouse efficiency that’s just shy of the plan and therefore… right on?

Whatever. It’ll make beer. Pitch yeast.

Brief Aside re: Brew Day Retro

From the strict perspective of evaluating the predictive power of the planned brewhouse efficiency it was on the one had very close, and on the other hand so far off. Planning for 3 gallons into the fermentor and getting only 2.5? That’s nearly 17% off on volume. Meanwhile, planning for an O.G. of 1.042 and getting an actual of 1.050? That’s about 19% over.

In other words… “Nearly nailed it in aggregate but… how about no?”

And I half-expected something like this. I was just starting to get used to how the numbers would shake out for my 5 gal. batch brew days on my system as I brewed outdoors. This was… completely different. And not only that, but I don’t think I’d ever brewed such a small batch in the 10 gal. kettle before.

Taking a moment to reflect on it, several things became clear. First, the amount of wort left behind in the kettle (with the trub) was going to be more-or-less constant compared with my “full size” batches. I’d failed to properly account for that. (Live and learn!) Second, I’d formulated the batch such that I would withhold 6 qt. of water for a mash-out but made an in-the-moment decision to just do it all together. Which might have been fine if I’d remembered to recalculate the strike temperature such that I would start in the right place. But I didn’t, and probably because I didn’t think that would be that big of a deal. (And now I’m maybe getting ahead of myself?)

Which is not to say that the experiment was a failure. There were some missed numbers, sure — and some attendant mistakes on my part. But there were also some great lessons learned! For one thing, I got some good insight into what was involved (end-to-end) for brewing these small batches on my stovetop. And I saw that it was possible! Second, I allayed some of my concerns around the immersion chiller when I observed that an ice bath operating on approx. 3 gallons was able to get it to acceptable temperatures only slightly slower than my immersion chiller outside. I learned my kitchen ergonomics leave a lot to be desired, but that these are things I can work around.

I learned I would do a stovetop small-batch again, and it would work better next time.

Fermentation

All that brew day retro stuff aside, I got the wort into a PET carboy, got that into the basement, and pitched my yeast. And the next morning (approx. +11 hours post-pitch) there were some bubbles in the airlock, and some krausen on the surface, and… the stick-on thermometer reading in the mid-60s ºF.

And/but/so: I was keeping this one low-tech and low-effort. I was going to be hands-off and walk away for a while. Wherein I couldn’t help but notice at approx. +48 hours that the krausen had mostly fallen, and the bubbles in the airlock had mostly stopped, and the stick-on thermometer was reading on the low end of the 1084 yeast’s published range but… #RDWHAHB right?

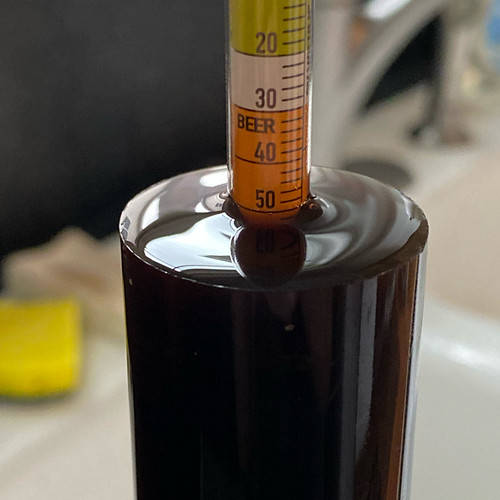

Fast-forward to approx. +168 hours (one week) since pitching and… there’s like nothing happening. Nothing in the airlock. No visible krausen. Stick-on thermometer reading in the low-60s ºF which just so happens to be the basement’s ambient temperature. Take a small sample for gravity: 8.2ºBx which BeerSmith tells me is 1.021 after factoring in the O.G. etc.

That seems too high to me. The estimated F.G. was 1.011 so it seemed we had at least another several points to go. Strategizing, I fed it 0.5 tsp./gal. of yeast energizer, gently agitated the wort, and brought it upstairs to rest it next to a heater where my hope was that the yeast would be roused and bring it down another … 5 points?

I check again three days later and… the exact same refractometer reading. (Bummer!) As-is? A 3.8% ABV beer with approx. 57% apparent attenuation. ABV-wise? Close enough I suppose. Attenuation seemed… super low, especially given that the F.G. was a good 10 points higher than the by-the-numbers style guideline information. I thought about just packaging it that way but… something about that didn’t sit right with me. And drawing a large enough sample to taste seemed to reinforce that — it seemed underattenuated.

The Nuclear Option?

Later that afternoon, I just decided to go nuclear on this would-be Irish Stout. Stuck at 1.021? Yeast energizer didn’t do anything? And neither did warming it up? (Because those things never do…?) I looked through my stash and found a 10 gram packet of glucoamylase enzyme.

“Is this a dumb idea?” I asked myself. And, after re-reading the dosing recommendation on the packet, I concluded that the most likely outcome was that it would do nothing.

So I dissolved it 10:1 into 129ºF water, then added it to the beer with crossed fingers.

Somewhat shockingly, the airlock was notably active just a few hours later. I could only conclude that the enzyme worked — that it broken down some of the longer chain starches leftover from the maybe-too-warm mash and now the yeast were going to town again.

Checking in again approx. 10 hours after adding the enzyme, I took another refractometer reading. Looking like 7.6ºBx which BeerSmith converted to 1.017 — OK: we’re moving the needle here.

I did a little more math: that was -0.004 over about 10 hours, and so if it kept a nice linear pace, then I could expect it at 1.013 after another 12 hours which is more-or-less where I wanted it to be.

Except that it wasn’t linear and 11 hours later it was reading 5.6ºBx which BeerSmith converted to 1.005 — and OMG WTF!? It’s a good thing that I had some potassium sorbate on hand to stop things before they got ever more out of hand.

Packaging

Wow! What a wild ride that was, eh?

So having successfully arrested any further fermentation, I proceeded to pressure test my brand new 3 gal. keg, then draw off a hydrometer sample, and then siphon the finished beer into that new keg.

My very small good fortune was that the (mischievous) refractometer underreported the F.G. by only one point, and my actual was 1.006 making the final ABV 5.8% and the apparent attenuation 87.6%. A dry stout? Oh for sure… but would it have body? Would it drink like an Irish Stout should? We would have to see.

Overall Impressions

I’m not totally sure what to make of this beer. It’s recognizably a stout, and yet… lacking in some of the roasted grain character that makes a stout a stout. Also that whole side quest with the glucoamylase and maybe I killed the body?

AROMA. Medium-low malt character; mostly a medium-low espresso and moderate toffee. Missing a distinct roasted grain character. Low hop nose; floral character like citrus blossoms. Medium-low esters with an impression mostly of black currant and ripe red apple. (That said — esters seem a bit high for style.) No significant diacetyl. No detectable acetaldehyde, nor DMS.

APPEARANCE. Jet black color with garnet highlights. Opaque. Thick tan head with creamy dense foam. Persistent. Visible, rapidly-rising carbonation.

FLAVOR. Malt character largely follows aroma, though less intense. Moderate espresso, low toffee, some background notes of bittersweet chocolate. Very low floral and herbal hop character, mostly retronasally. Firm bitterness, but in the moderate range, and seems low for style. A pronounced fruity ester impression — again mostly black currant and red apple notes — but intensity seems a bit high. Decidedly malt-forward balance. Semi-sweet impression on the finish but still manages to finish dry. Slight sourness in the mid-palate?

MOUTHFEEL. Moderately light body — seems a too light for style. Moderate, gentle carbonation. Moderately low creaminess. Detectable but not significant astringency. Threshold-level alcohol warming — not unpleasant, but shouldn’t have any.

OVERALL IMPRESSION. Seems like minor technical faults resulted in significant stylistic faults? Not unpleasant to drink, but doesn’t fit as an Irish Stout. Biggest issue is the lack of a distinct roasted grain impression, and esters that seemed to distract from the rest of the elements. Body also seems a bit too light. Ester impression suggests that it might work better as a 16C. Tropical Stout? It’s otherwise too dark and too strong to position as a Category 13 beer; and not nearly hoppy enough for Categories 19 or 20.

I’d like to take another swing at this beer sometime; it seems a real shame to have got it into the neighborhood and then still crashed and burned. I would like to think that the grist works as-is, and that I more controlled and cooler mash would give the resulting wort the fermentability that it needs. This would allow the beer to get into the right F.G. range without needing the … uh … “assist” from the glucoamylase toward the end there. Similarly, I think a slightly larger pitch would have helped, as would a better controlled fermentation. I think those three things together are what marred this beer. In other words, perhaps the less-fermentable wort would still have attenuated well-enough if there had been a big enough pitch at the beginning, and a warm-enough fermentation. Or else maybe I could have gotten away with the less-controlled fermentation if I’d pitched more yeast into a more fermentable wort, etc.

That is to say: I don’t think that this was a fault of the recipe, but rather some errors in process.

And that said: I’m still going to drink it all.

Sláinte!

Recipe

The all-grain (3 gal. small-batch BIAB) recipe for Murphy the Lucky Dog is as follows:

Water Chemistry

Starting with the Seattle municipal water profile (carbon filtered) as a base:

| Ca | Mg | Na | SO4²- | Cl- | HCO3- |

|---|---|---|---|---|---|

| 47.2 | 10.5 | 46.0 | 85.1 | 40.6 | 140.1 |

Grist

- 3 lb. Thomas Fawcett Maris Otter

- 1 lb. flaked barley

- 1 lb. roasted barley

- 4 oz. Proximity Black

- 4 oz. BEST acidulated malt

Hop Schedule

- 1 oz. Fuggle (40 min.)

Yeast

Wyeast 1084 Irish Ale

Brew Day

- Collect 17.15 qt. water and heat to 157.8ºF. Mash in; hold at 152.1ºF for 75 minutes. No mash out.

- Remove filter bag from water. Squeeze filter bag to extract as much liquid as possible for wort. No sparge. Pre-boil volume should be 3.89 gallons.

- Bring to a boil. Boil for 60 minutes; follow hop schedule as described above.

- Cool to 68ºF as rapidly as possible. Post-boil volume should be approx. 3 gallons.

- Aerate wort; pitch 1084 yeast from starter.

- Start fermentation at 68ºF.

Beyond Brew Day

- Allow fermentation to complete (approx. 2 weeks) at approx. 68±2ºF.

- When fermentation is complete, rack the beer to a keg. Carbonate to 2.4 volumes.

- Enjoy!

Details

Murphy the Lucky Dog, an Irish Stout by Tilde Gravitywerks

| Original Gravity | 1.050 |

| Final Gravity | 1.006 |

| ABV | 5.8% |

| Attenuation | 87.6% |

| IBU | 33 |

| SRM | 43 |

| Links | Flickr |

- Having previously done 15A and 15C…[↩]

- The name here is a whole side story in and of itself. The “Murphy” part is clearly (clearly?) a reference to Murphy’s Irish Stout which was a favorite of ours back at St. Mary’s, Guinness being an acceptable substitute &c. But somewhere in the early 2000s, while out to lunch (dinner?) with my wife at a local diner, I noticed this paper placemat with an advertisement for the local animal shelter and some of the animals up for adoption. Anyway, there was a photo of this dog “Murphy” and I tore the photo off the placemat and stuck it in my pocket and then nicely cut him out and laminated him. And I carried him around in my wallet for years. I never met the real Murphy, but I imagine he found a good home. Godspeed, Muphy — you lucky dog.[↩]

- The triumphant return of the ice bath! …since I don’t have a good way of hooking up my immersion chiller for my indoor brewing here.[↩]

Leave a Reply