Homebrew #17: Boo Beer

¶ by Rob FrieselMy fourteenth Tilde Gravitywerks homebrew 1 turned out to be the first… major disappointment colossal failure learning experience? I set out to make a simple pale ale (originally tentatively titled “Acorn Pale” 2) and what I wound up with, after a number of disappointing surprises, was the delicious and refreshing Boo Beer:

Boo Beer (née Acorn Pale) started out as a bunch of notes from my brewing journal. Simple pale ale? read one. Dry hop? Whole hops? Cascade! read another. And I saw that I had indeed not attempted a so-called simple pale ale yet. 3 I had this idea that, in addition to Honestatis, it might be nice to have a staple beer. Something that I could serve to friends that would be a familiar style. Straightforward base malts, familiar hops, and a clean yeast. I worked out the recipe (vide infra), got my ingredients together, and kicked into brew mode.

That’s when things got… unpredictable?

Right from the beginning, things did not go right. While getting the wort together for the yeast starter, it boiled over at least twice. (Small boil-overs, but boil-overs just the same.) The starter itself krausened big time and almost forced the foam stopper out.

Come brew day, this luck continued. I had a friend coming over to help with the brewing, and he ran late. (No big deal but indicative of things to come.) I got the liquor heated just fine, but when I added the grains, the temperature didn’t come down enough. 4 I added some cold water (about half a quart) and got it down to the right temperature. I did my usual towel wrap on the kettle and let it mash for sixty minutes. I made my first mistake when I decided to skip the mash-out. 5 When I lifted the filter bag out of the wort, I didn’t seem to get much more out after squeezing. I took a pre-boil reading and came up with 7.9%Br which seemed OK — but I didn’t bother to double-check where it should have been. 6 With my volume right around the target, I got the DME in there, stirred, came up with 15.8%Br (again, not double-checking the should be) and applied heat. Followed my hop schedule. Gave it 10 minutes to settle after flame-out. Had the right post-boil volume. Got it cooled to 70°F in just over 10 minutes. 7 The time to transfer had come.

It’s worth saying here that I’d gotten a brand new 6½ gal. carboy that I was dying to use, and this was to be its maiden voyage. But oh man… I’d forgotten plenty of prep work.

As I added the 2½ gallons of cold water to that carboy, I noticed that I’d never marked off lines for each gallon. Oh well. I could just make some guesses. Then we started to pour the wort over from the kettle… But the filter disc in the funnel kept getting clogged with junk. The hop cones weren’t a problem (they were easily removed), but the break material was frustrating. It took close to 30 minutes to pour everything into the carboy.

And then… more forehead slapping. The stainless steel baster that I’d historically used to take samples for gravity readings? Nope. It couldn’t reach the surface of the wort through the carboy’s neck. We tried tipping the carboy, but that didn’t work either. Ultimately we poured off a small sample into a bowl. Sigh.

Then the real bummer: gravity was 1.034, when it should have been 1.054. I cringed. Nothing like this had happened to any of my previous brews. Even my first partial mash was within one point of the target gravity. Deflated, I pitched my starter and carried the carboy down to the basement, grateful that at least the whole Cascade cones smelled amazing.

I tried to console myself with another note that I’d found in my brewing journal: Session ale recipe? Well, looks like I can cross that one off my list, too! 8

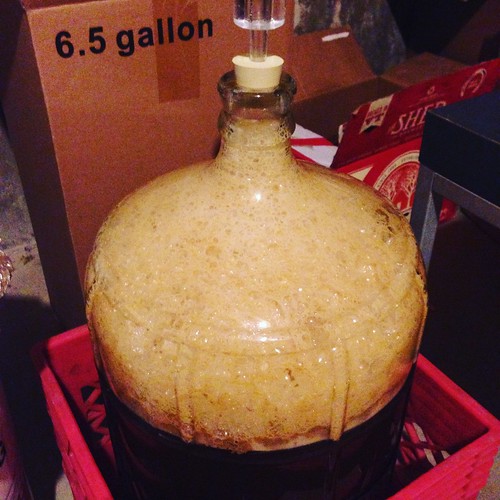

Fifty-two hours after pitching and I had a nice thick cap of densely foamy krausen in the carboy. So I had that going for me. But about five days after pitching, things had dropped off dramatically. The krausen had fallen, and there was almost no activity in the airlock. And while this was arguably right on schedule, the temperature had fallen to 59°F — and 1056’s published low end is supposed to be 60°F. Feeling nervous, I cleared a space in a closet on the main floor and brought the carboy upstairs, where its temperature rose to 63°F over the next couple hours.

At this point, I’m second guessing everything. Do I stay the course on my single-stage/single-vessel fermentation plan? Do I dry-hop for three days as planned? Longer? Shorter? What am I going to do for gravity readings if the baster doesn’t fit? Should I warm it further to try to rouse or reactivate the yeast? Do I need a diacetyl rest? Did I accidentally over-pitch? How did I wind up with that low-gravity?

A Brief Aside About Mashing and My Starting Gravity

While all this was going, I did a lot of reading and talking about that too-low starting gravity reading that I’d gotten for Boo Beer. I could accept that I hadn’t hit the mark, but I wanted to know why. And if I couldn’t know why, then I wanted at least some decent operating theories. Why were my first four partial mashes all within a point of the target gravity 9 and this one so far off?

Which isn’t to say that I naïvely thought I was going to get a definitive answer or anything like that. But through several blog posts, articles, and conversations, I ultimately concluded:

- Finer crush? As long as I’m doing BIAB, I may as well go with a finer crush if I can manage it.

- I should mash longer. There’s some nuance there about how this affects body, but overall: until I’m a more experienced masher, I’m likely to get better results by just letting it sit for 75-90 minutes at around 152°F or so.

- Don’t skip the mash-out. I’m still unclear on all the specifics here, but this being the biggest difference between this and my other partial mashes… don’t skip it.

- Watch the temperature. Don’t let it get to hot.

- Get everything you can out of the BIAB bag. Let it finish dripping. Give it a faux sparge and pour some warm water over it. Give it a couple good squeezes. 10

And/but/so the one that kept coming up? A longer mash.

An End to the Aside, and a Return to the Main Narrative

And so fermentation wrapped up. And so I settled on a day for bottling. And so I got that last ounce of Cascade ready for the dry-hopping. And once again, all my bad luck came pouring out.

My first plan was to get that ounce into an extra filter bag that I had. But I didn’t have any culinary twine to tie it off. Nor could I find any at the store. So I poured the hops into the bag and gave it a loose knot. But then I couldn’t get it through the neck of the carboy. 11 FML.

Having to abandon my original plan, I improvised. Grabbed my funnel, spray sanitized it, and stuck it in the neck of the carboy. Except that hop cones are large, and loose, and happily jam up the neck of the funnel. And no amount of poking them seemed to make any difference.

Improvising again, I took to scooping the hop cones out of the funnel and just jamming them through the neck… pretty much one at a time.

So be it.

Three days with the cones floating along the surface. Then it’s bottling day, and I start to feel like my luck is turning around. First of all, I had enough 22 oz. bottles for packaging. And I learned how to use my racking cane as a make-shift wine thief for that final gravity reading. (1.011! About where I’d want it to end, though hardly the best attenuation.) Racked. Mixed up with the priming solution. Packaged 24 × 22 oz. bottles. And about a pint worth left over to enjoy flat.

And you better believe it was enjoyable. That Cascade hop aroma and flavor. It was going to be little on alcohol, but big on flavor.

And boy did that ever turn out to be true. After carbonation wrapped up, the first bottle had everything I’d hoped for in the flavor: the malt backbone, the big citrusy aroma from the Cascade dry-hopping, and an assertive bitterness to balance it out. I’m still a bit bummed about missing the gravity, but the flavor is delightful. Would brew again.

Recipe

The partial mash recipe for Boo Beer is as follows.

Mash Grains

- 6 lb. Pale Ale 2-Row

- 1 lb. Caramunich I

Fermentables

- 2 lb. light DME

Hop Schedule

- 1 oz. Chinook (60 min.)

- 1 oz. Cascade (15 min.)

- 1 oz. Cascade (dry-hop 3 days)

Yeast

- Wyeast 1056

Prepare a 800 milliliter starter 2-3 days before brew day.

Brew Day

- Collect 13.41 qt. (approx. 3.35 gal.) water and heat to 172.8°F. Add 6 lb. Pale Ale 2-Row and 1 lb. Caramunich I to filter bag and add to water. Hold at 156°F for 60 minutes. 12

- Mash out. Heat to 168°F over 7 minutes; hold for 10 minutes. 13

- Remove filter bag from water. Squeeze filter bag to extract as much liquid as possible for wort.

- Top off to approx. 2.84 gal.

- Add 2 lb. light DME, and bring to a boil. Add 1 oz. Chinook hops.

- With 15 minutes remaining in the boil, add 1 oz. Cascade hops.

- Cool to 70°F as rapidly as possible and top off the fermenter to reach 5 gal.

- Aerate wort and pitch Wyeast 1056 yeast from starter.

Beyond Brew Day

- After fermentation completes, determine bottling date. Add 1 oz. Cascade to dry-hop for 3 days prior to bottling.

- Use corn sugar to carbonate on bottling day. Rack beer into bottling bucket and bottle.

- Allow at least 2 weeks to carbonate.

- Enjoy.

Details

Boo Beer an original dry-hopped “accidentally small” pale ale by Tilde Gravitywerks

| Original Gravity | 1.034 (7.9%Br) 14 |

| Final Gravity | 1.011 (4.8%Br) |

| ABV | 3.15% 15 |

| Attenuation | 67.65% |

| IBU | 41.1 |

| SRM | 11.3 |

| Links | Untappd Flickr |

- And seventeenth brew overall.[↩]

- Hearkening back a little bit to homebrew #5, Acorn Steam.[↩]

- Koru IPA comes close, being an IPA and all. And Little Ponder was an English pale ale, but in my mind these are “bitters”. One could argue that the original batch of Sorry Karl was something of a blonde ale. But none of them would fit comfortably into the APA bracket.[↩]

- To be fair, this has happened before, but still..[↩]

- I’m still not sure where I got the idea that it was OK to do this. I’m usually patient enough, so I must have read something somewhere that told me not to bother for BIAB. But I can’t find any notes to that effect.[↩]

- As an aside: it occurs to me that I haven’t really figured out how to interpret some of the numbers and steps on a BeerSmith brew day sheet, especially when it comes to BIAB and partial mash. It was unclear what the pre-boil gravity of the wort was supposed to be — both before and after adding the DME. And I’m not even sure that it specifies these numbers separately.[↩]

- The rapid cooling was a shocker to me. Normally it takes me about 20-30 minutes to get down to pitching temps. Maybe it’s because I did the 10 minutes stand after removing the kettle from the heat?[↩]

- I tried to talk myself into this idea that I’d just taken the reading incorrectly. I had all these notes around the Awkward Gingham brew day that suggested I’d made a mistake there. And there were similar notes on a couple other beers where back-to-back readings were off by a couple of points. But this was just so far from where it should be that I needed to accept that I’d just messed up something.[↩]

- Except for Acer Square, which was nine points over the target gravity, and probably because I underestimated the fermentable sugar contribution of the maple syrup.[↩]

- Some people will cry foul at that last part, citing tannins. But fuck that. I’ve never seen any evidence of that.[↩]

- A day or two later, I got the tip that I should have put the bag through the neck first, and then fed the hope cones through the neck. Oh well, live and learn.[↩]

- As noted above though, it would probably make sense to mash for longer than 60 minutes. My efficiency with these grains, at this temperature, for this time was… very low.[↩]

- Again, as noted above: I skipped this step. Which was, as far as I can tell, the main difference in the mash between this recipe and my previous partial mash batches. Don’t skip the mash-out![↩]

- Should have been 1.054. I was targeting 1.054.[↩]

- That extra 0.05% makes all the difference, right?[↩]

About Rob Friesel

Software engineer by day. Science fiction writer by night. Weekend homebrewer, beer educator at Black Flannel, and Certified Cicerone. Author of The PhantomJS Cookbook and a short story in Please Do Not Remove. View all posts by Rob Friesel →4 Responses to Homebrew #17: Boo Beer

Pingback: Homebrew #21: Summerclone | found drama

Pingback: Homebrew #25: Birdwatcher | found drama

Leave a Reply